Bend and Hold: Maintaining Traditions at Saito Wood

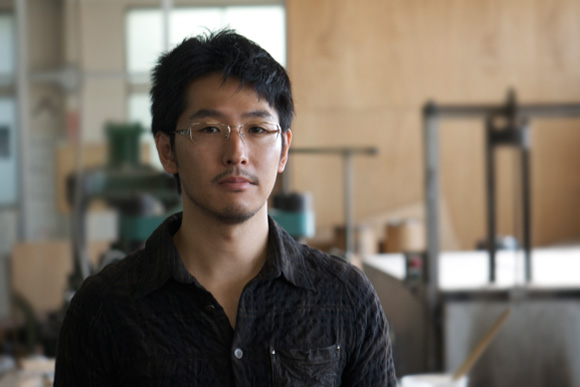

Awaiting me at the exit of the Shizuoka train station, Takuya welcomes me with a slight bow of the head and a firm handshake. He was able to pick me out of a crowd of more than fifty people getting off the Shinkansen (bullet train), so immediately I felt a bit out of place, as if everyone knew I was not from there. His first question was whether I had eaten, which I later learned is a common courtesy bestowed upon your guests in Japan. I usually only have coffee for breakfast, but nonetheless the gesture made me feel very welcomed.

Shortly afterwards, we proceed to drive approximately 30mins outside the city center to visit the Saito Wood production factory. Located in a painted green warehouse, I am greeted by a small entourage, amongst them Noboru Saito, Takuya’s uncle and the factory manager. I was expecting a much larger operation considering their presence in Japanese society, but obviously what lacks in size was more than compensated in an efficient enterprise. Touring the factory was a delight, as Takuya would later explain to me that his grandfather built many of the first plywood presses at the inception of the company. They have since modernized their machinery, but what remains is a dedication to the highest quality of molded plywood products in Japan.

Along the way back to Shizuoka, we take a slight detour to view Mt. Fuji from its southwestern perspective before I am afforded the opportunity to meet Takuya’s parents and the rest of the Saito Wood staff in their offices and showroom. The community aspect surrounding the brand was evident throughout my visit, and a big reason why I felt each and every product produced is crafted with such attention and care. I am honored to be able to call Takuya and his family my friends, and I hope you enjoy our interview illustrating the three generations of the Saito Wood brand.

The interview was conducted in English and Japanese. Both languages are published so as to not lose any meaning in translation for native readers.

Tell me about the origins of the Saito Wood?

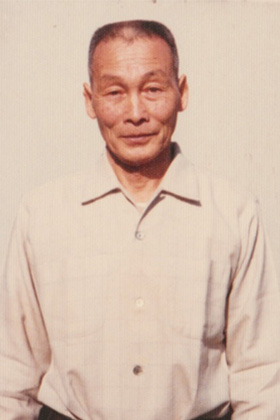

TS: The company was founded by my grandfather, Isamu Saito. In 1948, after the war, the company established a woodworking factory at a place called Kawane in Shizuoka prefecture, about fifty miles west of Tokyo. They manufactured everything from made-to-order furniture to baseball bats, but at this time, they were not working with molded plywood. However, operating an ordinary wood shop was a struggle, and my grandfather knew they would need to try something new, and remembered the molded plywood he had worked with during the war.

サイトーウッド会社の始めてについて少し教えてください?

私の祖父、齊藤勇がこの会社を作りました。1948年、戦後静岡県の川根というところで木工所を作り、注文家具から野球のバットまで様々な物を作っていました。この時はまだ成型合板の技術を使っていませんでした。しかし 普通の木工所では経営が厳しく、何か新しいことをしなければいけないと考えていたときに成型合板を思い出しました。

How did your grandfather learn to work with molded plywood?

TS: During the Second World War, he was employed at a factory for the Japanese army in the city of Takayama in the Hida district in central Japan. Because iron was in short supply in those days, they were researching ways to manufacture various necessary items from other raw materials. My grandfather was working on how to make fuel tanks out of wood, and learned about techniques for molding plywood. At that time he was producing items about the size of wine casks. Initially, he only made some round accessory cases from it, stacked them up in a trailer for his bicycle, and went around selling them.

成型合板を加工するのは、どうやってできるようになりましたか?

第二次世界大戦中、彼は飛騨高山の日本軍の兵器工場で働いていました。当時日本は鉄が不足していたため、いろいろな物を鉄以外の素材で作る研究をしていました。祖父が研究していたのは燃料タンクを木で作る研究で、そこで成型合板の技術と出会いました。その時はワイン樽ほどの大きさの物も作ろうとしていたそうです。丸い小物入れを作ってリヤカーに積んで行商していた。

Saito Wood started as a family business. Is your family still actively involved in the company? What role do they play now in the company?

TS: Yes, we are. As the face of management I am involved in sales, marketing, long-term planning, design – everything, really. My younger brother Yoshiaki is in charge of material procurement and oversees production planning at our factory.

サイトーウッドが家業として始まったが、斉藤家は会社の営業にまだ積極的に関与していますか? 会社にはどういう役をしていますか?

私は代表取締役として経営、営業、企画、デザインなどの全てに関わっています。また、私の弟が工場の材料調達、製造計画など全ての管理しています。

“When we think about new products, we have to design them in a way that takes twisting and warping into account, which is the biggest challenge.” – Takuya Saito

How many people are involved in the manufacturing of Saito Wood products?

TS: Our company employs fifteen people – ten in the factory, and five in the management division of the company.

御社の木造製品の製造は、何人関与していますか? 工場の従業員は何人いますか?販売部など、何人雇っていますか?

工場に10人、営業部は5人です

What is your favorite aspect of working with bent plywood?

TS: You can produce unique curves that are striking and beautiful, of the sort that aren’t possible when working with solid wood. It’s also light, strong, and easy to work with.

成型合板を加工するのは、一番好きな点は何ですか?

独特の曲線が美しく、魅力的です。これは無垢材では表現できません。軽くて丈夫、そして加工が容易だからです。

What is the greatest challenge?

TS: When molded plywood is pressed, it warps and twists, and controlling that during production is difficult. When we think about new products, we have to design them in a way that takes twisting and warping into account, which is the biggest challenge.

成型合板を加工するのは、最も大変な難題は何ですか?

成型合板はプレス後に「ひねれ」や「ゆがみ」が発生するので、それをどのように抑えるかが難しいです。新しい製品を考えるときは「ひねれ」や「「ゆがみ」を考慮したデザインをする必要があります。

What is your favorite Saito Wood product?

TS: I like our small, medium, and large-sized Ayous waste paper baskets. These products are “Saito Wood” to me.

御社が作ってる製品の中に一番好きなのは何ですか?

小、中、大型のアユースのペーパーバスケットの方がが好きです。これこそ「サイトーウッド」です。

Can you explain the steps in making the Ayous Paper Waste Baskets?

TS: The production of this item begins with the raw wood being cut into a fan-shape 0.6 mm thick. Next, glue is applied and the wood is inserted into a metal mold. The mold is then inserted into a large kiln and heated for about 20 minutes at 100 degrees centigrade. After that, the wood is taken out of the metal mold, and trimmed along both edges. Finally, the bottom plate is fitted in, and the basket is finished.

アユースのペーパーバスケットの工程の一歩を説明してくれますか?

アユースのペーパーバスケットを作る場合、まず最初に0.6mmの材料を扇形にカットします。次にそれらに「のり」を塗り、金型に入れます。次にその金型を大きな窯に入れ、約100度の熱で20分間加熱します。その後、金型から材料を取り出し、両端をカットします。そして底板を取り付け、塗装して完成です。

Lastly, what is the future direction of the brand?

TS: We intend to continue making paper baskets and trays. It is a simple goal, but in this day and age, achieving a simple goal is not a simple matter.

御社の将来進路は何ですか?

これまでと同じようにペーパーバスケットやトレーを作り続けることです。単純な目標ですが、今の時代、そう簡単なことではありません。