It was early February when I received an email from Steve at Nalata Nalata.

The email was about the following; about 3.5 years ago, Steve and his wife Angy were chatting with Makoto Koizumi over coffee in NYC, during Koizumi-san’s exhibition “Shiro and Shiro” at NN. Steve casually mentioned how they would like to have kids and asked Koizumi-san to design a rocking chair for that time in their life. Time had passed, and Steve and Angy had their first baby, Keo, last autumn. Just after a few months, Koizumi-san finally completed the design of the Tonton Rocking Chair.

“What perfect timing. I was really surprised,” says Koizumi-san, smiling joyfully. Koizumi-san had made the rocking chair slowly but diligently, without any idea of Angy’s pregnancy and childbirth. I interviewed Koizumi-san about the backstory of the rocking chair and his thoughts behind his design.

ーー What was your impression when you heard about a rocking chair from Steve for the first time?

The image that came to my mind was a grandma sleeping on a rocking chair while knitting. A swinging chair to make us sleepy. Is that necessary for us? That was honestly my first impression. Actually, it was a bit hard for me to picture, but once Steve told me that it’s a chair to put the baby to sleep, I was like, “Ah, that totally makes sense!” I felt that I’d like to make the chair.

ーー Actually, I’ve misunderstood that it’s a small rocking chair for kids…

Hahaha, seriously? No, no, it’s not. It’s a chair that a parent holding a baby sits on. It’s difficult for us to imagine a chair to put a baby to sleep, isn’t it? Once I realized that it’s furniture for a purpose, I felt that there’s meaning I should design.

ーー The purpose of the chair to put a child to sleep must have ignited your designer’s spirit. Is this your first time to design a rocking chair?

Yes, it’s my first time. Since the rocking chair is not familiar in Japanese lifestyles, I haven’t come up with the idea of making it. Miyazaki Chair Factory, who is in charge of manufacturing the rocking chairs this time, have never produced one either. Miyazaki-san, the CEO of Miyazaki Chair Factory, agreed with me. “Sounds nice. Let’s get it together.” Then our rocking chair project started.

ーー The name is Tonton. Did you name it?

Yes. I named it after the sound “Ton Ton” when parents pat the back of babies to try to put them to sleep.

ーー While Mom or Dad holding a baby sits on a rocking chair, the baby stops crying imperceptibly and falls asleep. Then Mom or Dad also starts having a doze. Tonton chair reminds me of such a peaceful scene.

It feels warm, right?

ーー By the way, when you start designing a chair, what is your first step?

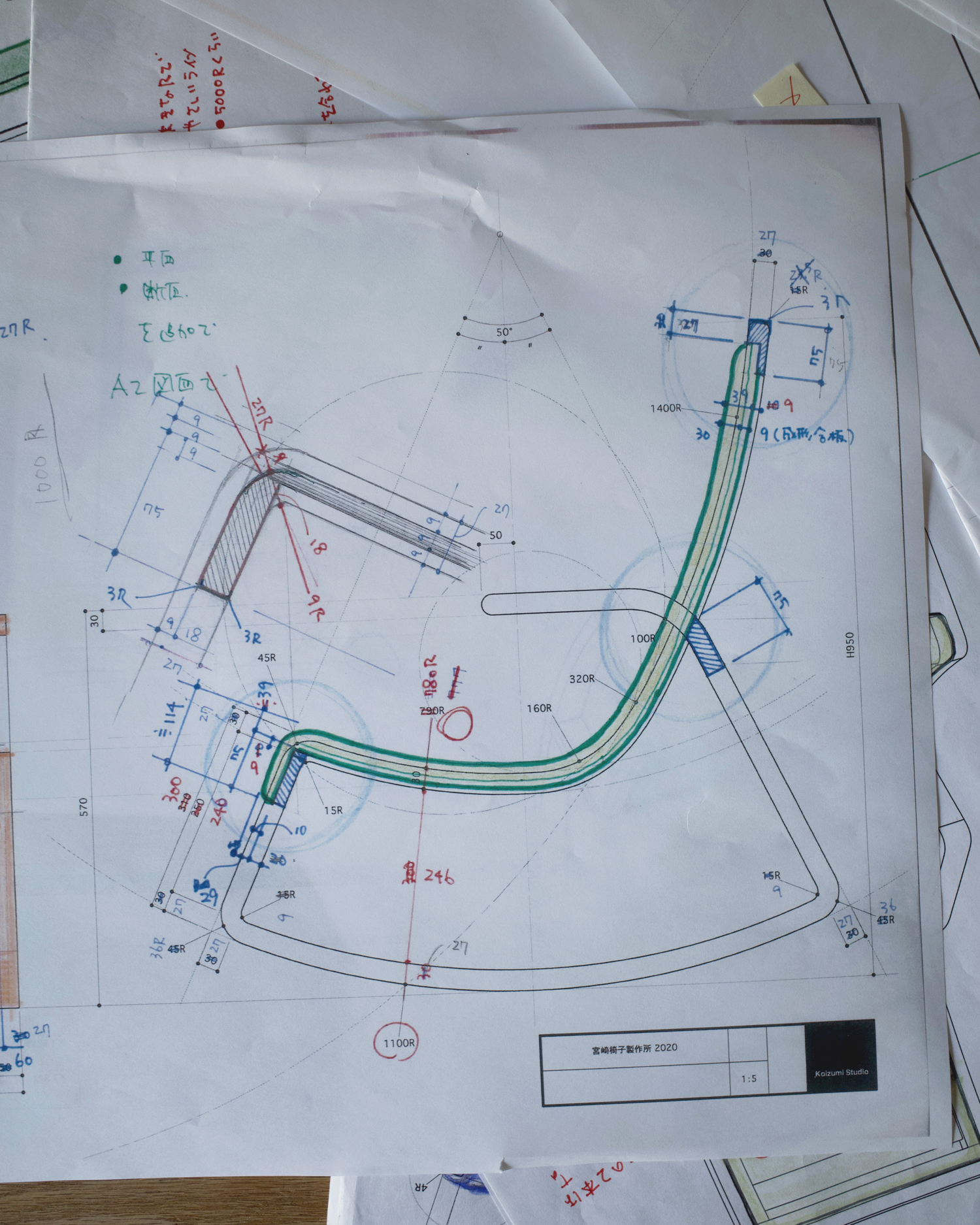

In this case, since the rocking chairs originated from Windsor furniture and Shaker furniture, I started by picking up the dimensions from those chairs to get an idea of the size and curves.

ーー After that, you would make sketches and drawings?

After I drew my very first sketch, I asked Miyazaki Chair Factory to create a prototype. That is how we produce a chair all the time

ーー What?! Instead of making adjustments on drawings, you start with creating a prototype?

Right. We start with creating a prototype in actual size, then Miyazaki-san, the staff at Miyazaki Chair Factory, and I discuss the details in front of the prototype, like “we should adjust here, or there”. Especially when it comes to chairs, there are many unclear parts you don’t know about until you sit on them or you produce them. That’s why I don’t draw detailed drawings and we create a prototype at the beginning based on my rough sketch. We repeat trial production over and over again, discussing things like, “how about lowering the height of the seat?” or “let’s increase the curve.”

ーー Wait, do other designers follow the same process as you to make chairs?

In general, no. First the designer makes an accurate drawing, then the maker manufactures it according to the drawing. Our method of manufacturing, which we call a workshop, is very unusual. You know, it has been over 20 years since I started work with Miyazaki Chair Factory. I have been regularly visiting their factory every two months since then. When I visit their factory, I sit on the prototype to make sure. It took around two years to complete the tonton, so we created almost 10 prototypes.

ーー Workshop, what a good word. It sounds like all of the staff produced something together, rather than the designer just designed it.

I think so. Both Miyazaki Chair Factory and I always produce chairs from scratch with a trial-and-error process, that’s why we do workshops. I admit that it takes more time than usual, but something careful and exceptional is born. It’s also great learning for the staff by discussing and producing together.

ーー Oh, I remembered that I read an article written by a staff member at Miyazaki Chair Factory online. “The product designed by Koizumi-san is very simple, but at the same time, they have very unique characteristics… Also difficult tasks are always planted by him.” It sounded like they were forced to do difficult tasks by you. I laughed.

Hahaha! No, no, I’ve never forced them! Since I understand almost every technique and machine in their factory, I discern what they can’t and also what they possibly can do. For example, to produce a rocking chair this time, I suggested, “Let’s try bending it!” We never tried large bending before. Trying something one step at a time makes both Miyazaki Chair Factory and me grow.

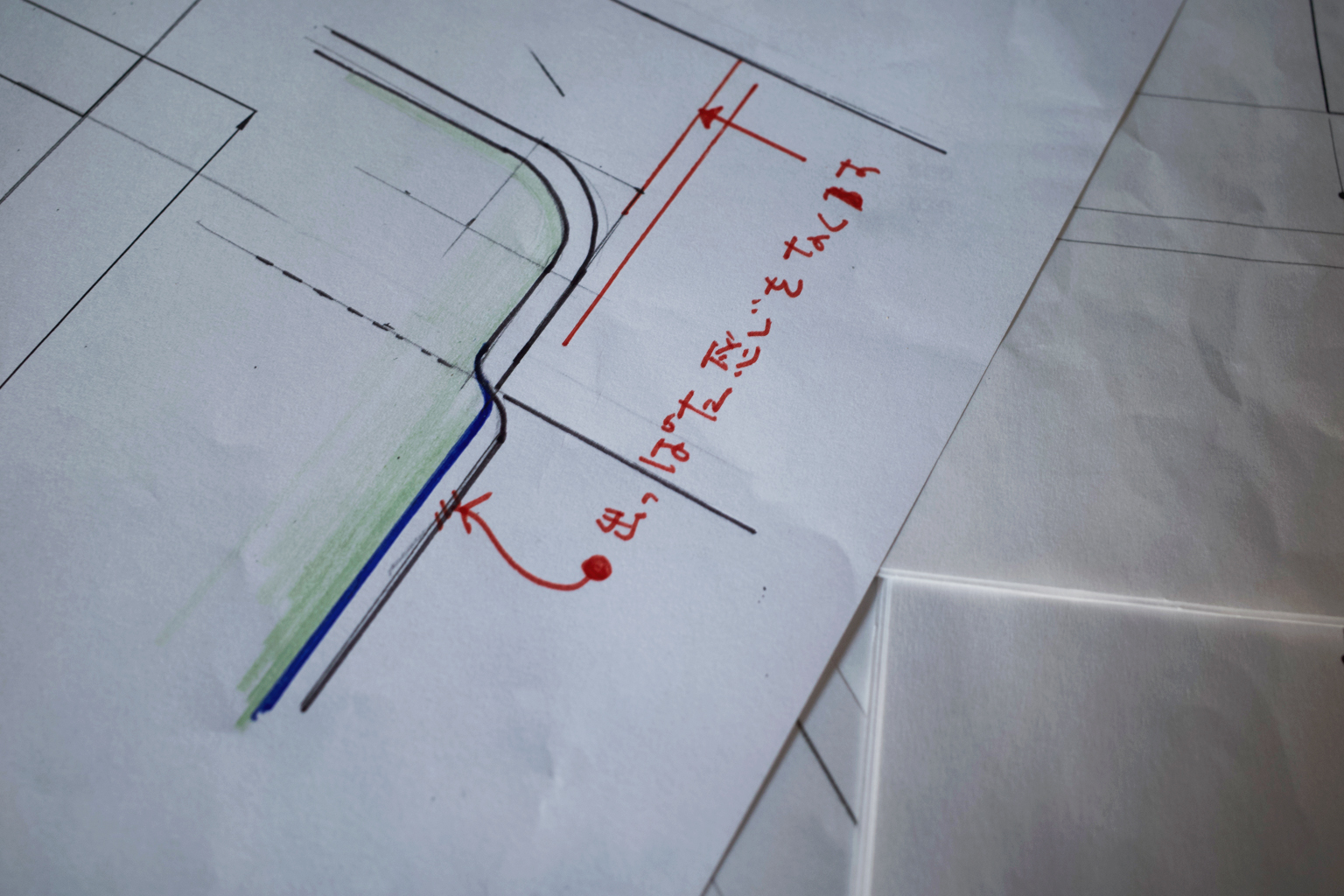

ーー What is “large bending”?

It means bentwood. The wood is steamed first, then placed in a mold (metal or wooden) and pressed with strong force to bend. At Miyazaki Chair Factory, we’ve done bentwood for the backrest of the chair before, but we never did it for large and long parts such as the backrest or foot of the rocking chair. Miyazaki-san jokingly told me, “It was super hard!” (laughs)

ーー Any other parts that you felt were difficult?

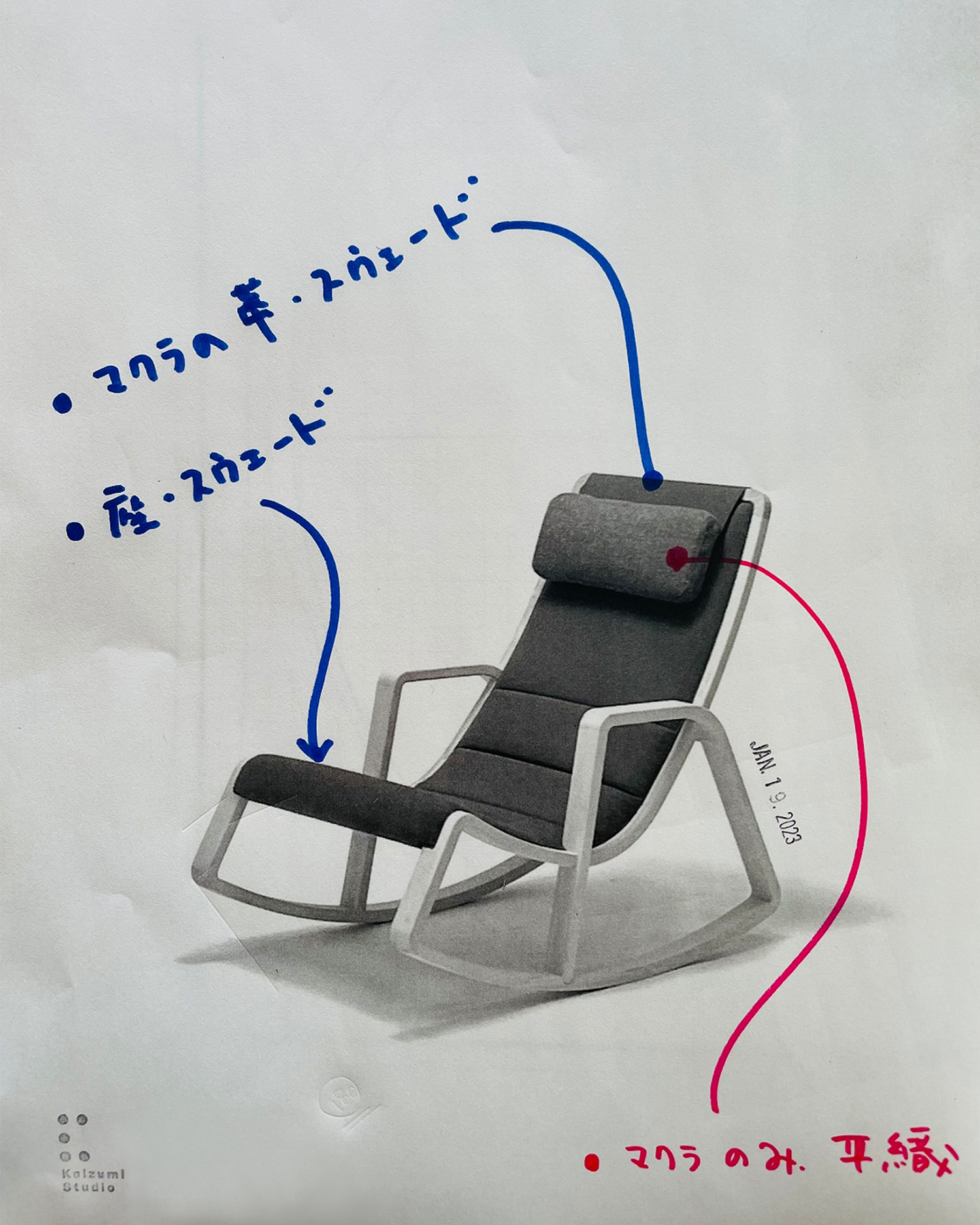

I struggled to find a stable and comfortable posture on the swing chair. Our goal was a lounge chair, where we can lean back comfortably and relax. In order to bring our chair closer to our goal, we sat on the prototype many times in the factory and meticulously made adjustments like cutting and connecting the prototypes. Upholstery was also a difficult part. When we applied fabrics to the backrest, the fabric rose easily from the surface unless we made stitches. We made full use of our idea to attach fabric on the backrest. Ah, you see a pillow on the backrest? It’s not fixed, it’s movable like it raises and lowers. There is a groove carved in the back, and a bar sticks into the groove and goes up and down. I hope Steve and Angy will be surprised like, “Oh my God! The pillow moves!” (laughs)

ーー It’s obvious, but there is tremendous effort, skill, and thoughtfulness in every detail.

Well, it can also be said that it is a chair made wholeheartedly.

ーー By the way, when you design products, are you conscious of Japanese-ness?

I’m not. Products designed by Japanese designers and manufactured by Japanese factories would create something Japanese-ness, maybe?

ーー Japanese design is often recognized as simple or minimal overseas—the same as Koizumi-san’s products, isn’t it?

Minimal is generally defined as stripped downed or minus design, right? But from my point of view as a designer, I think that’s not true. Minimalism in Japan is surely a result of addition.

ーー What?! Not minus but addition?!

Let’s take Udon noodles as an example. When we hear of “minimal Udon”, we must imagine Su-Udon (just Udon noodles in the dashi soup without any toppings), don’t we? Some people say that while there are many types of Udon, like Tempura Udon (tempura topped) and Nabeyaki Udon (Udon stew topped with shrimp and vegetable), Su-udon is a type of Udon where all toppings get eliminated. I disagree with that. By choosing bonito flakes carefully, making dashi broth, and kneading buckwheat by hand, the process of making Su-Udon relies on addition. Su-Udon is a final product of adding until a maker thinks that’s enough.

ーー Wow! That makes sense.

Japanese design may look simple, but it’s the result of the addition of skills and training to achieve the form. It’s the same as Japanese architecture. We choose carefully what is truly necessary, from essential materials to fundamental construction methods. We add those things then quit at the point where we think that’s good enough. I think such results can be said are Japanese style.

ーー What a mind-blowing perspective. The Japanese don’t aim to make something simple or minimal. It’s just the result of addition? Do you think there is any “-ism” in your design or production?

I would say that sustaining a long relationship with the manufacturer and keeping production sustainable are my style. I often address that there are three different types of design in the world.

ーー Three types of design?

Design to be sold quickly, design made to be known widely, and design to be sold slowly. The first is something trendy and epoch-making. The second is something unique to attract attention. No need to sell a lot. Something buzzworthy and helpful that makes the name of the manufacturer widely known would be appreciated.

ーー Some designers collaborated with ceramic makers to create eccentric products. That’s exactly it, right?

That’s right. Murata Seisaku-kun (the robots created by Murata Manufacturing Co., Ltd.) is also the same. On the other hand, there is enduring design such as the one Sori Yanagi created. Judging which is better or worse is meaningless. The only important thing is that both designer and manufacturer share the same purpose.

ーー So, Koizumi-san, whose theme is sustainability, is engaged in the third type of design, right?

As I worked as a designer, my design gradually became so. When I look at the products in the world today, I’m also intrigued by the things “designed to be sold slowly”.

ーー What are the essential things to do so?

I often say that the skill of the maker (manufacturer), the materials of the region, and the can-do spirit are the most important things. Whether the manufacturer has strong motivation and enthusiasm or not—that is the criteria. I think Miyazaki-san has a can-do spirit for sure. That’s why we have been able to work together for a long time.

ーー Well, is there anything Koizumi-san is willing to achieve beyond production?

You know what? I really want my products to become antiques.

ーー Antiques?!

Antiques are really impressive. When I thought about why I’m so obsessed with antiques, I came to a conclusion. One of the reasons is that they are tough. I don’t mean toughness or strength. It means the sustainability of materials. For example, there is warmth in old wood and there is fragility in old paper. Another reason is sufficient performance. It’s difficult to use it if it’s insufficient, and it’s easy to get bored if it’s over-sufficient. The other reason is emotional. It can be said “Emoi” in teen slang (laughs). It is feeling a sense of the “beautiful” or “adorable” in stuff. Actually, I’ve designed products based on such a philosophy, so I hope my products will become antiques eventually.

A rocking chair in the living room or bed room, which makes a baby fall asleep through gentle swinging, will be passed down from parents to children, then children to grandchildren. The Tonton Rocking Chair, which Koizumi-san and Miyazaki Chair Factory produced slowly but diligently, makes me imagine such a peaceful future. I hope the Tonton will be loved slowly but surely for a long time until one day it becomes an antique or until far more into our future.